When do Hydraulic Hoses Need to be Replaced?

When a hydraulic hose fails, it brings your hydraulic system to a halt, can put your employees in danger, potentially damages your system, and leads to a mess that could have environmental ramifications. The best way to prevent a hose failure is to recognize the signs of impending failure, perform replacements before that failure occurs, and take measures to prevent avoidable failures in the future.

Hydraulic Hose Basics

Hydraulic hoses are used to transmit fluid through your hydraulic system, often at extremely high pressures and speeds. They are vital to the proper operation of your hydraulic system, whether it is a hydraulic power unit on an airport runway or the hydraulics that power an excavator at a construction site.

The Main Job of a Hydraulic Hose

Hydraulic hoses must contain fluids while they are being transmitted while also protecting them from outside contaminants (e.g., water, air, particulate matter). Hose failure means that (a) the hose is no longer able to contain the fluid and/or (b) it can no longer prevent outside contaminants from gaining access to the fluid. When a hose fails, it not only affects system performance but can lead to serious damage and expensive repairs to the components within the system.

Anatomy of a Hydraulic Hose

A hydraulic hose is made up of three parts: the tube, the reinforcement, and the cover. The tube is the innermost part of the hydraulic hose and it is what comes into contact with the hydraulic fluid that flows through the system. Next is the reinforcement, which gives the tube the necessary strength to handle the high pressures involved with transmitting hydraulic fluid. The reinforcement usually takes one of three forms (spiral, braided, or helical) and is made from wire. The outermost layer of a hydraulic hose is the cover, which is designed to provide protection to both the tube and the reinforcement. Additional protective covers may be added to protect the hose from extreme heat or abrasion.

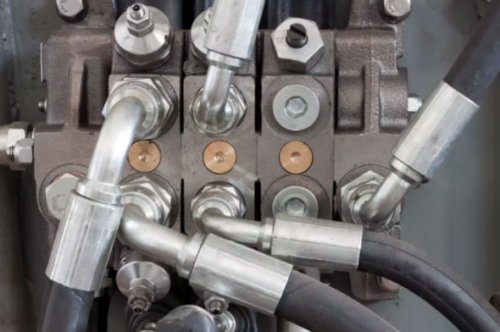

The Hose Assembly

A hydraulic hose assembly is composed of a length of hose with a fitting at either end. The fittings are usually made of stainless steel, carbon steel, or brass and include the outer portion called the socket and an inner portion called the stem that goes directly into the inner tube of the hydraulic hose. The hose assembly, rather than just the hose, is what actually connects different parts of the hydraulic system through ports.

Common Hose Issues

Hydraulic hoses should last between one and two years with many lasting up to ten years, so if the hoses on your equipment are failing in less than two years, then there are external factors that are reducing their life. Temperatures in excess of the recommended operating temperature, especially if the hose is making physical contact with a component that has extremely high temperatures, can cause otherwise good hoses to fail. Contact with components that involve vibratory motion can lead to surface wear, abrasions, or cuts that shorten the useful life of a hydraulic hose.

There can also be issues with chemical compatibility that can compromise the integrity of the hose, and that can include the hydraulic fluid used in the system or external chemicals that the hose is exposed to (e.g., cleaning compounds, oils, grease, corrosive chemicals). The tube material of the hose should always be selected so that it is compatible with the media that will be flowing through it. If there is incompatibility, the hose will weaken and eventually fail.

In addition, using a hose that is not rated for the operating pressure of the system can lead to damaging surge conditions whether the pressure is too high or too low. This unsuitability may be the result of the type of hose material or the type of reinforcement used in the hose. In addition, hydraulic fluid contamination can lead to wear within the hose as well as premature hose failure.

Hose assemblies must be put together correctly, and the type of fitting must be compatible with the port it will be used with. The fittings themselves must be installed correctly as well or there is a risk of a leak.

Natural Aging of Hydraulic Hoses

Both hoses that are in use and replacement hoses that have been left on the shelf for too long can fail simply due to their age. Hose assemblies will age, and with time they become brittle and prone to cracking. That is why you will often see a manufacture date on hoses and assemblies. Installing a degrading hose can lead to failure because its brittleness will not be able to withstand the high pressures involved with hydraulic system operation. Hoses should always be stored in a regulated environment that is not exposed to extreme temperatures.

Signs that a Hose Needs to be Replaced

One of the best ways to prevent hose failure is to perform scheduled inspections at least once a month. There are several different things to look for during such an inspection, including these signs of impending hose failure:

- Twisted hoses, which can lead to structural weaknesses in the hose and eventual leaks

- Kinked or crushed hoses, which can lead to higher pressures around the kink and localized stresses that can weaken the strength of the hose

- Abrasions and cuts along the outer hose cover (that go beyond the normal scratches and knicks), which can lead directly to hose failure if the cause is not addressed

- Corroded or cracked fittings, which indicate the hydraulic hose assembly needs to be replaced right away

- Worn spots on a hose, which can weaken the integrity of the hose

- Exposure of wire within the hose, which means the strength of the hose may have been compromised

- Leaks around hose fittings, which signal either hose wear around the fitting or damage to the fitting

- Oil running along the length of the hose, which indicate that the hose has failed and must be replaced as soon as possible

These are all signs that the hoses on your equipment are in need of replacement, and routine inspections reveal these potential issues before they turn into expensive (and dangerous) catastrophic failures. In addition, keeping a log of hose inspections can point to sudden changes in hose characteristics and can be used to identify hoses that may be aging past their useful life.

Hidden Hose Problems

However, not all impending hose failures may be obvious. In some instances, leaks can cause the hose to swell but, because of the strength of the reinforcement layer, the tube swells inward instead of outward. This leads to a reduction in the inner diameter of the tube which can cause changes in the velocity and pressure of the fluid flowing through the hose. Eventually, the tube can begin to pull apart internally and the end of the hose may blow off. Including pressure checks as a part of regular hose inspections can aid in revealing hidden problems such as this.

The Safe Approach to Finding Hose Leaks

If you suspect that a hose is leaking, never attempt to find a leak in a pressurized hose using your hand even if you are wearing gloves. Contact with highly pressurized hydraulic fluid can lead to an injection injury where the fluid is trapped beneath your skin. Such an injury should be treated immediately. The safe approach to finding the source of pinhole leaks in your hydraulic system is to use a piece of cardboard or plywood as opposed to your hand.

Preventing Hose Failure From Reoccurring

When a hose fails before its useful life has ended, it is important to track down what caused that failure to occur. For example, kinks or hoses pulled too tightly are due to poor planning and installation methods that can be avoided when it is replaced. A failed hose that was not rated for the correct temperature can be replaced with a hose that is correctly rated. If a hose fails due to rubbing against another piece of equipment, it can be rerouted away from that same area or a protective covering could be used. Many causes of premature failure can be addressed and avoided.

Conclusion

Hydraulic hoses will eventually wear out or suffer damage, but rarely do they fail without some type of sign. The best way to determine when hydraulic hoses need to be replaced on your equipment is to perform regular inspections to look for signs of impending failure and keep careful logs of those inspections along with the installation dates for replacement hoses. Preventative maintenance, therefore, is the key to avoiding hose failure and the downtime, expensive repairs, and safety issues that invariably accompany it.

Needfitting Hydraulics

At Needfitting Hydraulics, our technicians will come to your site to inspect your hoses as part of a regular maintenance plan. They have the skill and equipment needed to perform quality repairs and replacements to prevent hose failure and can be counted on to follow all related safety procedures. Our technicians also know the right type of hoses your system needs, taking into account key aspects such as chemical compatibility, pressure ratings, and temperature ratings. You can also rest assured that hose installations performed by Needfitting Hydraulics team members will be done according to industry best practices to promote the life of your hydraulic hoses. Contact the experts at Needfitting Hydraulics today to find out what we can do to help your hydraulic systems run at peak performance!

中文

中文

English

English